Rubberhog wheels are your best solution for grinding rubber and other elastomer materials. These wheels perform much better than simple abrasive wheels because of their unique construction. They are made of precision-machined steel forms, coated with long-wearing, specialized brazed carbide coatings. Most are pre-dressed to maintain rapid material removal, yet produce a desirable finish on most elastomer materials. They can provide a service life as much as hundreds of times that of conventional abrasives.

Roll grinding applications

One of the features that make Rubberhog wheels your best choice for elastomer grinding is the wide selection of coating types and coarseness sizes. These broad coating choices assure the best match to your specific requirements.

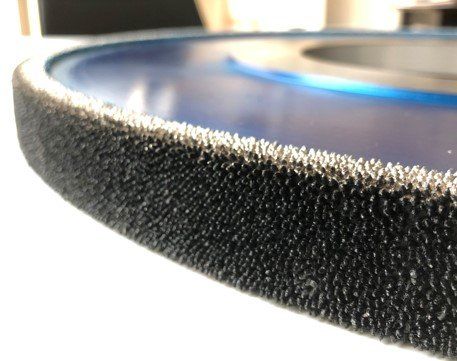

Rubberhog SSG and MCM coatings utilize very sharp teeth, which are shaped so as to provide fast penetration into the material, and unrestricted flow of grinding swarf away from the wheel. This provides a free-cutting action similar to a milling device, drastically reducing the time required for grinding.

Despite the free-cutting aggressiveness of SSG or MCM teeth, their very uniform height and shape provides for surprisingly smooth finishes on the work-pieces.

Example of SSG 390

Coarseness size

Selection of the coarseness size is primarily based on the hardness range of the material to be ground. Harder materials grind better with coarser wheels, while softer materials generally require finer wheels. If you must grind a wide range of material hardness with just a single wheel, select a general-purpose coarseness size appropriate for the range of hardness you will grind. For maximum effectiveness, Dual-Grit or Triple-Grit wheels are usually the best choice when grinding new products with overbuild.

We are at your disposal to assist you in selecting the correct grinding wheel for your application.

Rubberhog wheel design

Rubberhog wheels are custom-designed and produced to match your machine and product requirements. Selecting and ordering the optimum Rubberhog for your application requires gathering information about your grinding equipment, the type of grinding jobs you perform, and the materials which you grind. There are four primary aspects of wheel design to consider: Physical dimensions, wheel style, coating type, and coarseness grade.

High performance Peeler Tools

Rubberhog offers very effective peeling tools for removing large amounts of elastomer material quickly, without heat or smoke. This system consists of a tool-post holder, and replaceable, re-indexable peeler insets.

Rubberhog peeler inserts feature a wear-resistant carbide coating for long service life. The carbide coating contributes a self-sharpening effect, but as the peeler inserts wear, they can be indexed by rotating in the holder to provide multiple fresh edges.

- Rapidly strip old rubber from cores

- Save time by machining off overbuild

- Removes rubber quickly without heat or smoke

- High performance & long wear life